Soon (Dec 2010).

Equipment and Machinery

Briquetting: A wide variety of substrates are produced from the leftover processes which include bagasse and folio of reeds, rice hulls, peanut shells, egg shells, coconut shells and bits, wedges and leftover scraps of fabric, saw dust, coal dust, organic waste from sewage, chemical waste and fertilizer, cellulose linters pulp and paper industries, alfalfa, and many others. This briquetting machine will process these substrates, so as to facilitate their collection, transportation and blasting, and depending on region and conditions where they are deployed, can transform them into the usable and lucrative product of briquettes.

The machine is strong, extremely simple to use, requires low maintenance, operates dry with a 100 HP engine, and can produce briquettes in diameters of 36, 75 90 mm. Its production capacity, using saw dust as a parameter, with humidity at 10% input is 1 T/H. The Electrical Instrument panel is stationed at the machine’s base and is pivotal in providing easier setup and operation.

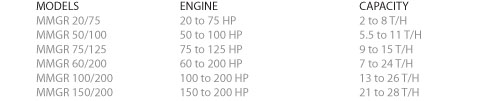

Pelletizers: Extremely high technology and efficient machines intended for the manufacture of pellets for animal ration, such as: birds, cattle, horses, rabbits, prawns, etc. Our pelletizers allow Matrix alteration of the peripheral speeds of 10.2 m/sec (ideal for serving chicken) to 6.45 m/sec (ideal for serving shrimp). With a simple switch of a pulley system they can be adapted for the manufacture of other products, such as bait Formica, citrus, soy bran, etc.

We have several models, with capacities that vary from 1 to 35 tons/hour with models that support main engine power from 15 to 350 HP (according to customer need).

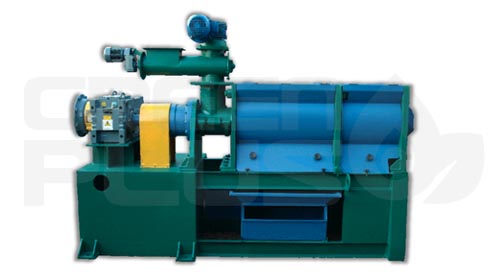

Hammer Mills: High technology manufacturing and extremely efficient for grinding grains, with speeds that vary from 15 to 250 HP. These machines are extremely tough and versatile.

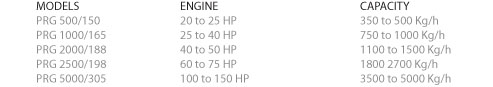

Presses for extracting oils from grains and oilseeds: Our presses were designed for the extraction of oil in three versions, for 1 T/H, 2 T/H, and 3 T/H. These machines have: a pressing chamber, basket, feeding system, and adjustment mechanisms.

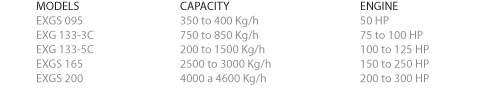

Extrusion of grains and oilseeds: High technology equipment built to withstand harsh operating conditions during the extraction of oils from grains and oilseeds. The machines are strong and extremely simple to install and operate. They enable complete control of the production process within the required parameters including: urease activity, palatability, solubility, etc. Working in parallel with the oil press, the client has complete control of the production process producing all of its grains and extracting the desired amount of oil and thus having alternative product sales ensuring the best cost-benefit structure. Benefits include: low maintenance, easy operation, long life span, and a carbon steel base offering strong support for the main engine. Transmission via V-belt pulleys, and an optional speed reducer which will work with engines from 150 to 250 HP.